What are the advantages of Chinese-made stone coated metal roofing tiles over those from other countries

Stone coated metal roofing tiles, as the mainstream material for modern building roofs, Chinese-made products have developed unique advantages in terms of technological iteration, cost control, and international adaptability. They have not only rapidly gained popularity in the domestic market but also demonstrated strong competitiveness in global competition. The following is a systematic analysis of the differentiated advantages of "Made in China" from six dimensions:

I. Cost and Capacity advantages: The scale effect drives global supply

Large-scale production reduces costs: Chinese manufacturers have increased production capacity by independently developing equipment (such as horizontal drying channels and automatic flip plate systems), achieving a single-line production speed of 4 to 10 seconds per piece, and reducing energy consumption by more than 30%, making the terminal price 15% to 20% lower than that of similar products in Europe and America.

Complete industrial chain support: From aluminized zinc steel plate base materials, colored sand sintering to the manufacturing of automated equipment, China has formed a full industrial chain support system, shortening the delivery cycle and ensuring the stability of supply. For instance, Shenggoban Company can export an average of 26 tons (about 1 container) per day to the African and Southeast Asian markets.

II. Technological Innovation and Process Breakthroughs: Solving Industry Pain Points

Leading weather resistance technology:

It adopts aluminum-zinc coated steel plate base material (aluminum-zinc alloy layer ≥150g/㎡) combined with water-based adhesive, with a salt spray corrosion resistance service life of over 30 years, and has passed the six new protection tests added in the T/CSTM 01408-2024 standard (such as anti-peeling and anti-fading).

Optimize the adhesion process of colored stones, such as the "inductive sand bucket" for precise sand control and the water dust removal system to reduce glue contamination, which increases the adhesion of colored stone particles by 40%. The color retention performance in the artificial accelerated aging test exceeds the international standard by 200%.

Anti-extreme climate design:

The locking structure and lightweight (only 1/6 of the weight of cement tiles) can withstand typhoons of up to level 12. Its seismic performance has passed the 9-degree fortification test, making it suitable for seismic zones and areas with frequent typhoons.

The low thermal expansion coefficient base material and slope drainage design solve the cracking problem caused by freeze-thaw cycles, and still maintain toughness at -30℃.

III.International Standard Adaptability and Service Localization

International standard adaptability and service localization

Strong standard compatibility: Leading Chinese enterprises (such AS Saint-Goben) simultaneously comply with standards like AS/NZS 1562.1 in Europe and the United States and EN 506 in the European Union, and were the first to pass the strict building materials certification in Australia, breaking through the market barriers of developed countries.

The overseas service system is well-developed: offices have been set up in Africa and Southeast Asia, equipped with multilingual technical support teams, providing full-process services from design adaptation to construction guidance. For instance, Saint-Gobain's localized warehouses in Tanzania, Vietnam and other places have shortened the delivery cycle to 7 days.

IV. Green Manufacturing and Policy Dividends

Multi-scenario solutions: Applicable to wooden structures, concrete roofs, steel structure venues, etc., especially skilled in old house renovation (no need to remove the base layer).

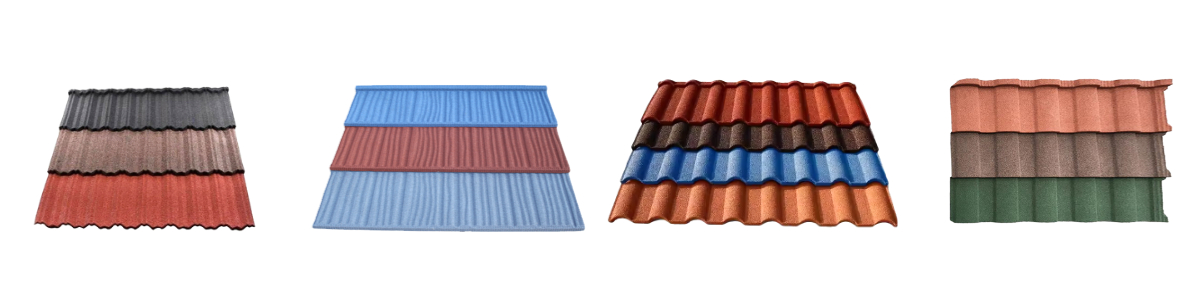

High design flexibility: Offering 8 major types of tiles including antique style, Roman style, and grid style, as well as over 15 kinds of colored stone tones, to meet the aesthetic needs of European-style villas, cultural and tourism projects, etc.

VI. Summary of Core Advantages Compared with International Competitors

Dimension | Advantages of "Made in China" | Typical characteristics of international competing products |

Cost | The price is 15%-20% lower and the production capacity is highly flexible | The brand premium is high and the customization cycle is long |

Technical indicators | The weather resistance exceeds the national standard by 200%, with a wind resistance of up to level 12 and an earthquake resistance of 9 degrees | Some brands have slightly better corrosion resistance (such as Nordic products) |

Environmental protection | Water-based adhesive process +100% recycling | Some still use solvent-based glue |

Service response | 24-hour after-sales service, strong logistics support, and flexible handling of any customer issues | Relying on agents, the response is relatively slow |

Chinese stone coated metal roofing tiles have made breakthroughs in both the infrastructure of developing countries and the high-end market of developed countries, thanks to their industrialized cost reduction capabilities, breakthroughs in weather-resistant technology and green attributes. In the future, as the 2025 version of the technical specifications issued by the Ministry of Industry and Information Technology strengthens the management of the entire life cycle, "Made in China" will further shift from "cost leadership" to "standard leadership", becoming a key supply force in the global green building wave.